01

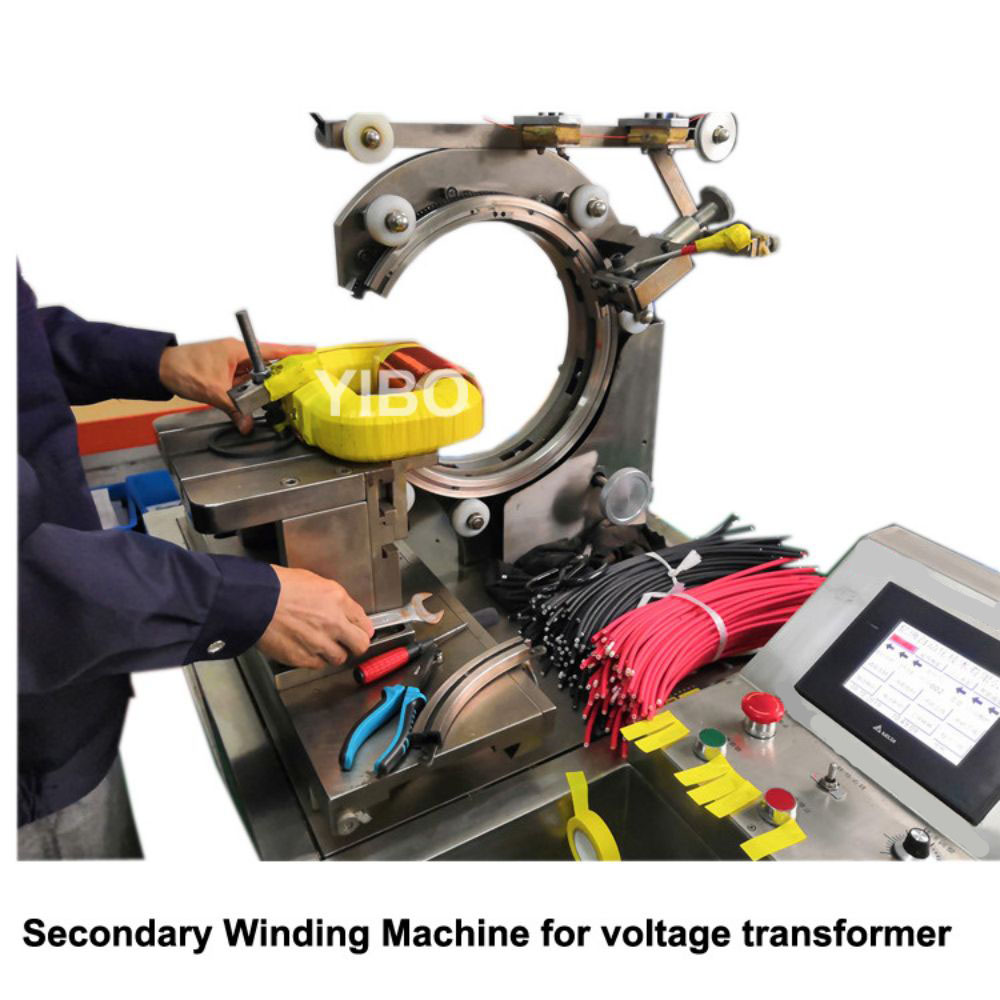

Advanced CNC voltage transformer ring winding machines

Product Description

CNC winding machines for voltage transformer secondary have been extensively proven since their introduction on the market. It has high winding precision, wide applicability, easy operation, convenient adjustment and strong versatility. Its stable, reliable and efficient performance has been well received by users, and it has become the most advanced CNC equipment for voltage transformer secondary coil winding.

Main Features

State-of-the-art control system: The main control system of the winding machine adopts the advanced Mitsubishi PLC programmable controller to provide precise control and efficient operation. All data is set on the touch screen, which also automatically calculates the wire length. The machine has an intuitive and user-friendly interface that makes it easy to adjust and monitor the winding process.

Efficient Winding Process

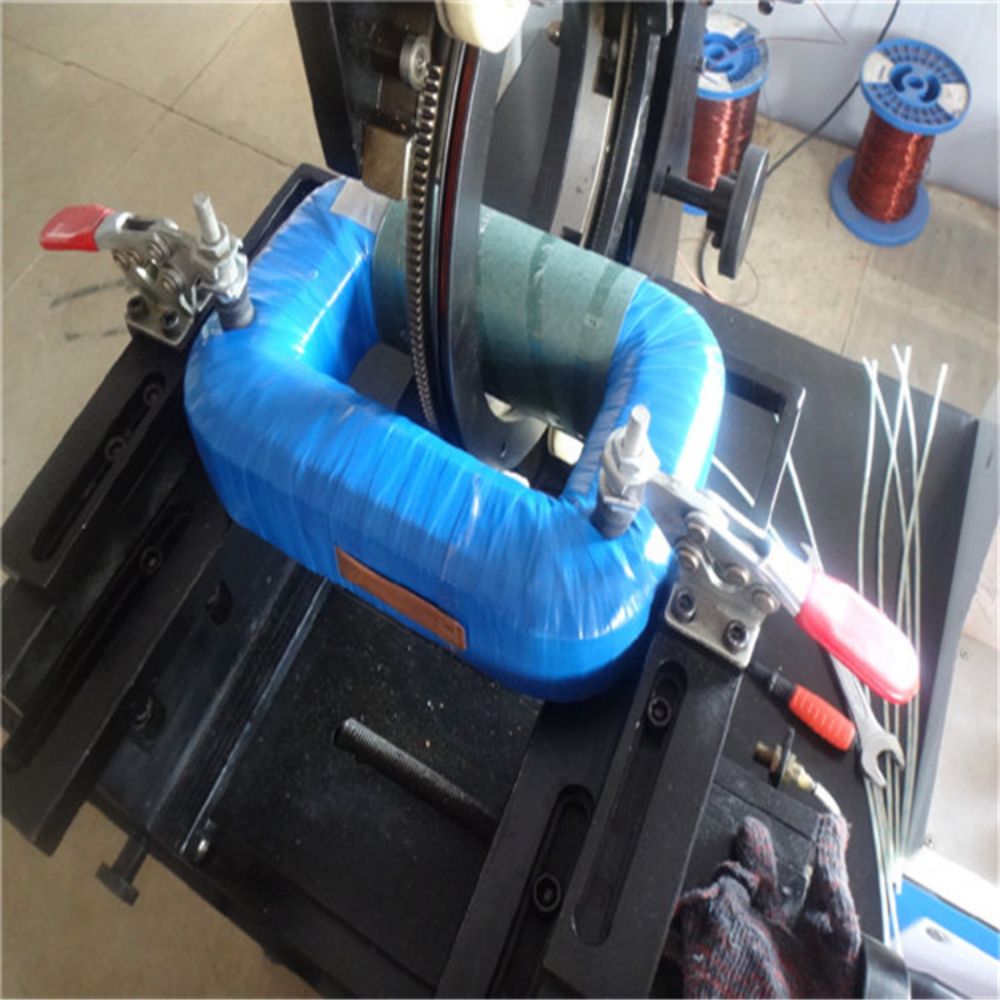

The fixed part of the machine core consists of horizontally movable ball guides and a vertically adjustable worktable. The workbench can be adjusted according to the thickness, length and width of the core, ensuring correct alignment between the core, winding ring and storage ring. The winding ring moves relative to the core, allowing efficient winding of the secondary coil.

Increase efficiency and save costs

The machine has a reasonable and compact structure design and a wide adjustment range, which can meet different winding requirements.

It effectively solves the labor-intensive process of manual winding of the secondary winding of closed voltage transformers, improves work efficiency, and ensures accurate number of coil turns. The enameled wire has uniform tension during the winding process and can be adjusted according to different wire diameters to prevent damage to the electromagnetic wire.

Compared with manual winding, this machine saves enameled wire and reduces the overall cost of the product. It also improves the overall electrical performance of the transformer, making it more cost-effective.

Application

CNC winding machines for the secondary side of voltage transformers are widely used in the manufacturing of voltage transformers. It is particularly suitable for applications requiring high secondary coil winding accuracy, versatility and efficiency. It effectively replaces the labor-intensive manual winding process, increasing productivity and ensuring consistent quality.

This advanced CNC winding machine guarantees stability, reliability and high performance. Its user-friendly interface and convenient adjustments make it efficient and easy to operate. With its cutting-edge features and superior functionality, it sets a new benchmark in CNC winding equipment.