01

Advanced high-precision current transformer CNC winding machine

Product Description

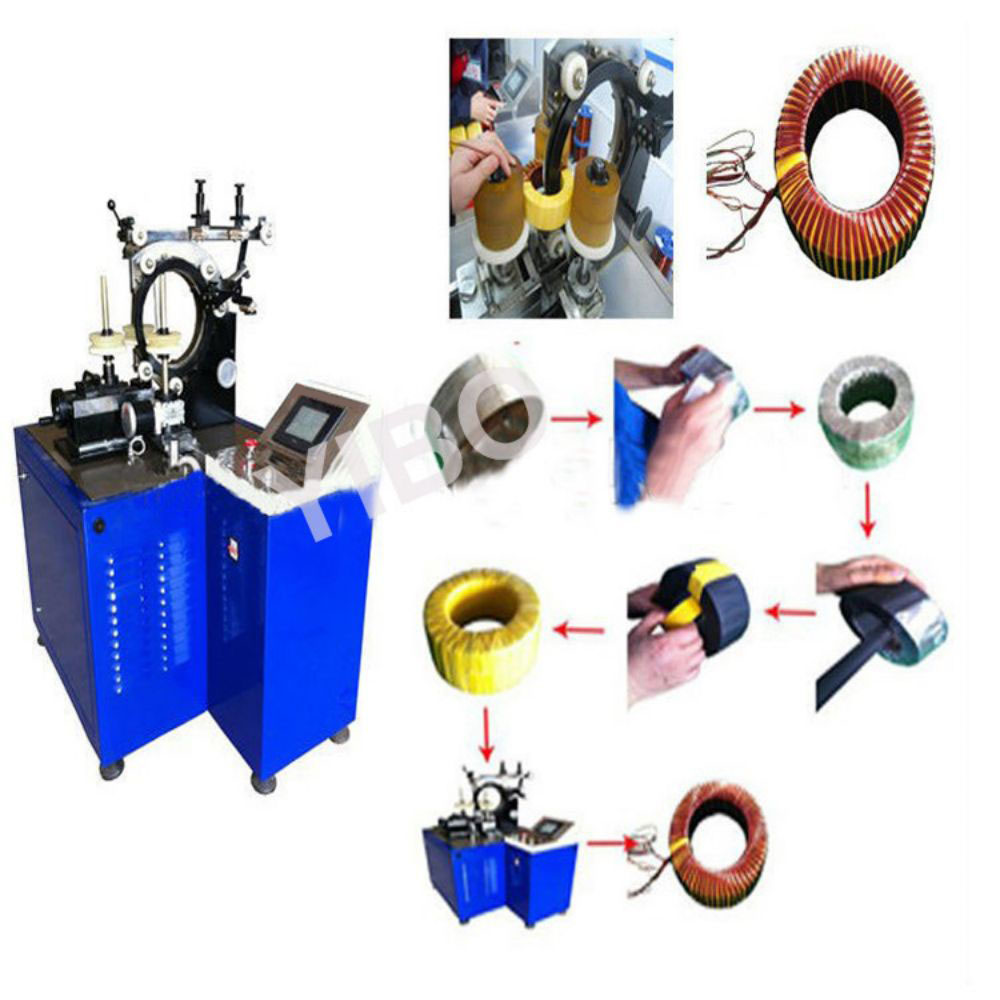

Our advanced high-precision current transformer CNC winding machines are specially designed for the electrical industry.

This machine is used to wind coils on ring-shaped iron cores, especially suitable for winding enameled wires. It is developed according to domestic advanced technology and the latest requirements of the current transformer industry, ensuring excellent accuracy and efficiency.

Main Features

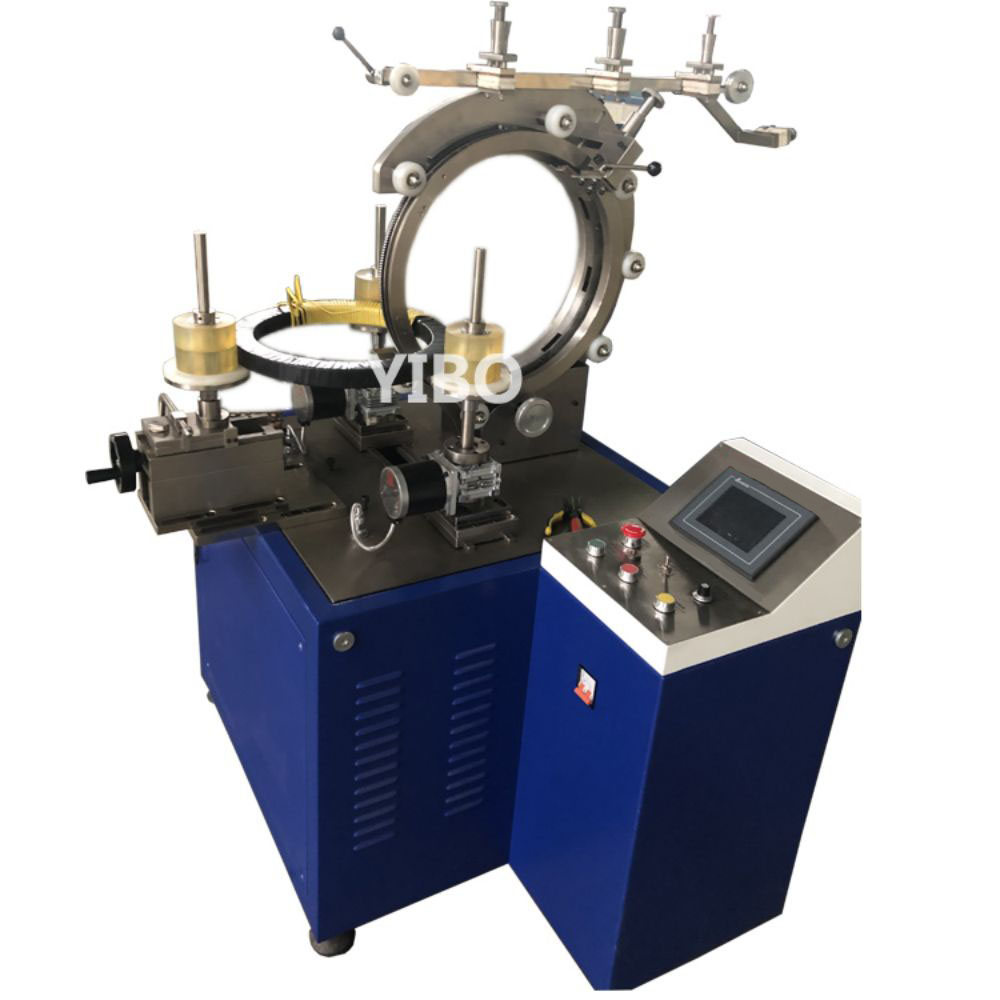

Cutting-edge PLC programmable main control system

The most advanced PLC programmable control system is adopted to enhance operational reliability. Program settings can be easily adjusted via the user-friendly touch screen interface.

Modular design and efficient electrical control: All electrical control components adopt modular design to reduce maintenance costs.

The main drive adopts frequency conversion control, with short drive chain, large starting torque, wide adjustment range, energy saving and noise reduction.

Stepwise winding control using stepper motors: The breakthrough design uses stepper motors and high-precision gearboxes for precise step control, replacing traditional mechanical gear transmissions. Achieve seamless stepless speed regulation from 0.01mm to continuous increments, ensuring high precision and torque.

PLC programming technology can realize automated functions such as line storage, counting, automatic parking, and parking memory, significantly reducing manual operations.

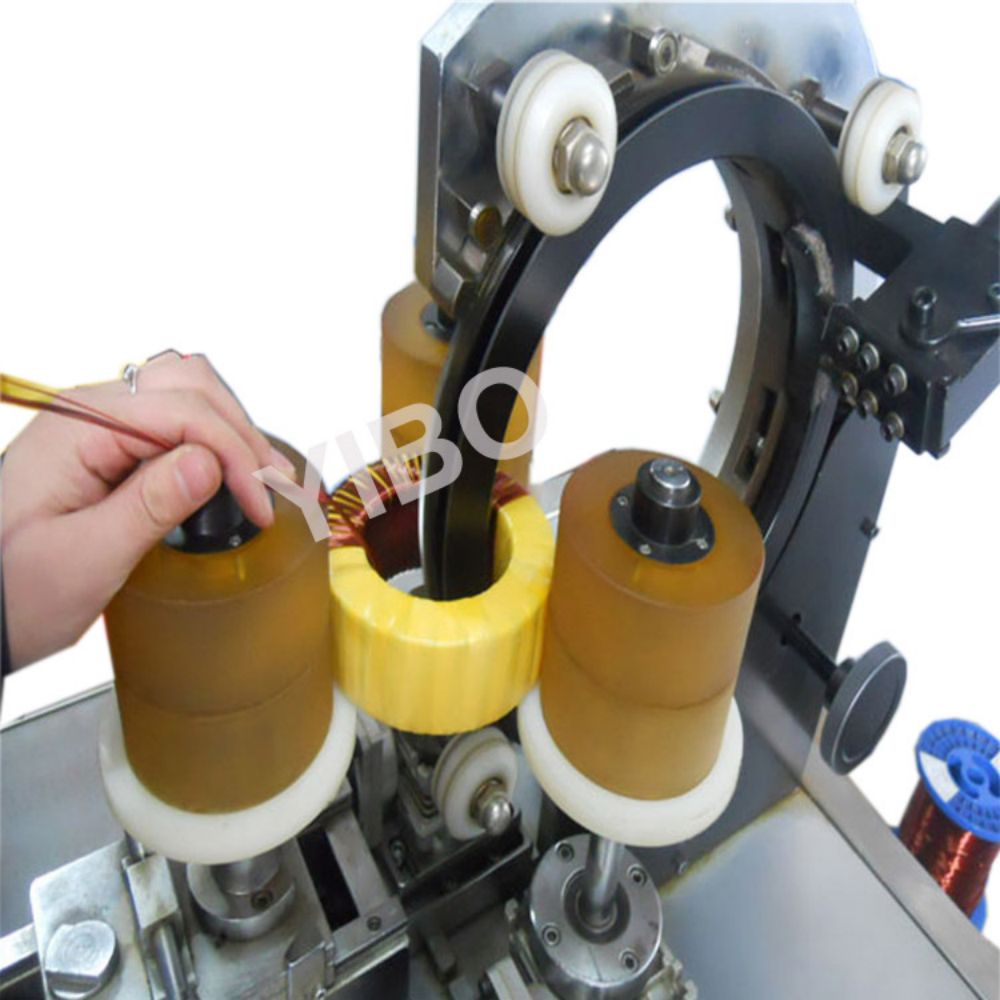

Multiple winding options: Specifically designed for single-wire, double-wire or multi-wire multi-layer windings, it effectively solves the complex challenges of multi-wire precision winding in toroidal current transformer windings.

Provides adjustable tension to accommodate different wire diameters to avoid any magnet wire damage.

Compared with manual winding, it minimizes the consumption of enameled wire, reduces the overall size of the transformer, reduces production costs, enhances comprehensive electrical performance, and significantly improves comprehensive economic benefits.

Application

Our advanced CNC winding machines are ideal for the current transformer industry.

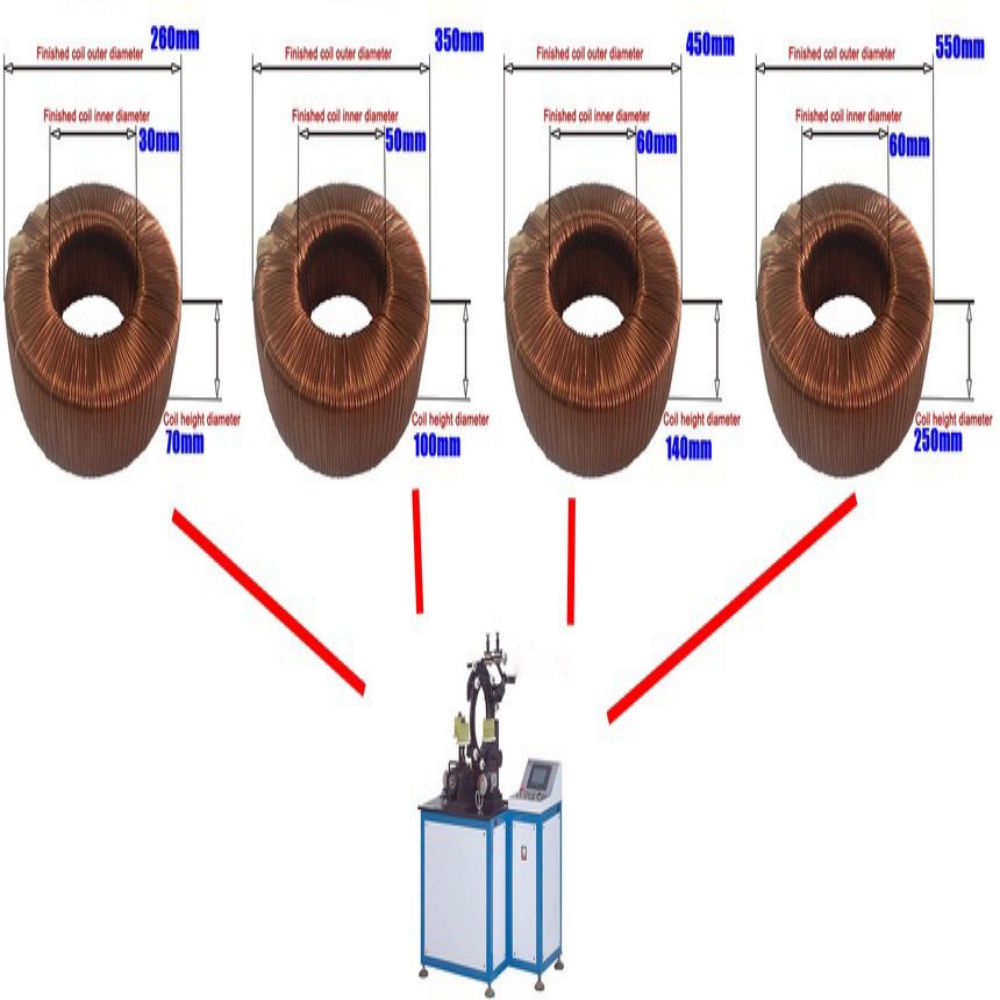

It can efficiently wind the coil onto the toroidal core, thereby enabling mass production and adapting to various coil varieties.

Our CNC winding machines have won unanimous praise from users for their high winding precision, wide applicability, user-friendly operation, convenient adjustment, excellent stability and efficiency. It represents the latest progress in CNC winding equipment.