01

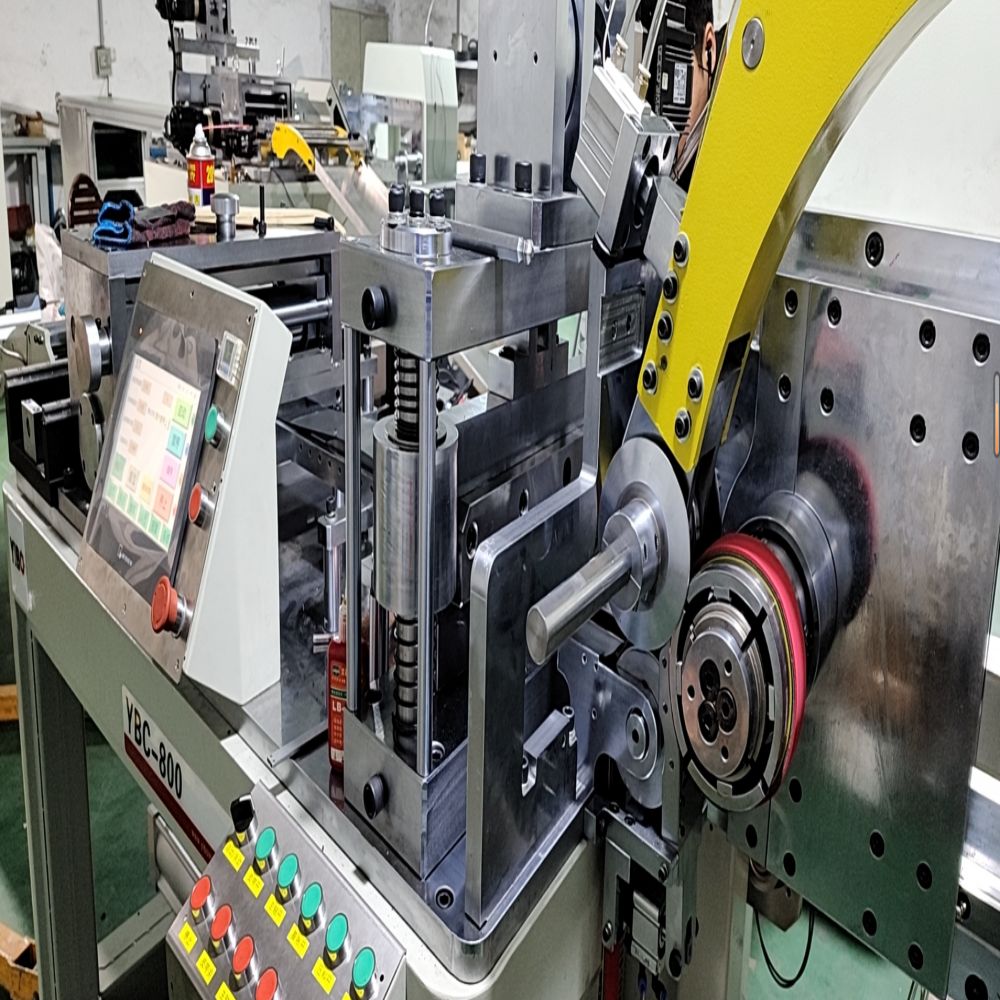

Advanced winding wound core toroidal winding machine

The machine is equipped with the latest computer system and servo drive technology to control the complex process of feeding, cutting and rewinding. It has extensive processing capabilities, accommodating strip widths up to 250 mm and achieving a maximum core outer diameter of 800 mm. The machine provides a highly flexible, precise and reliable production system for distribution transformers. It combines the inherent advantages of wound core technology, such as extremely low core losses, fast assembly and high throughput compared to the required capital investment.

Main Features

Fully automatic operation: The machine automatically completes the processes of feeding, guiding, winding, winding, and cutting without manual intervention, significantly improving production efficiency.

German Siemens control system and HMI touch screen: The machine is equipped with advanced Siemens control system and user-friendly HMI touch screen interface. This combination ensures high computing speed, powerful functionality and easy-to-operate, seamless production control. Multifunctional toroidal core production: The machine is capable of producing distributed gap cores and toroidal cores to meet various industry requirements and applications.

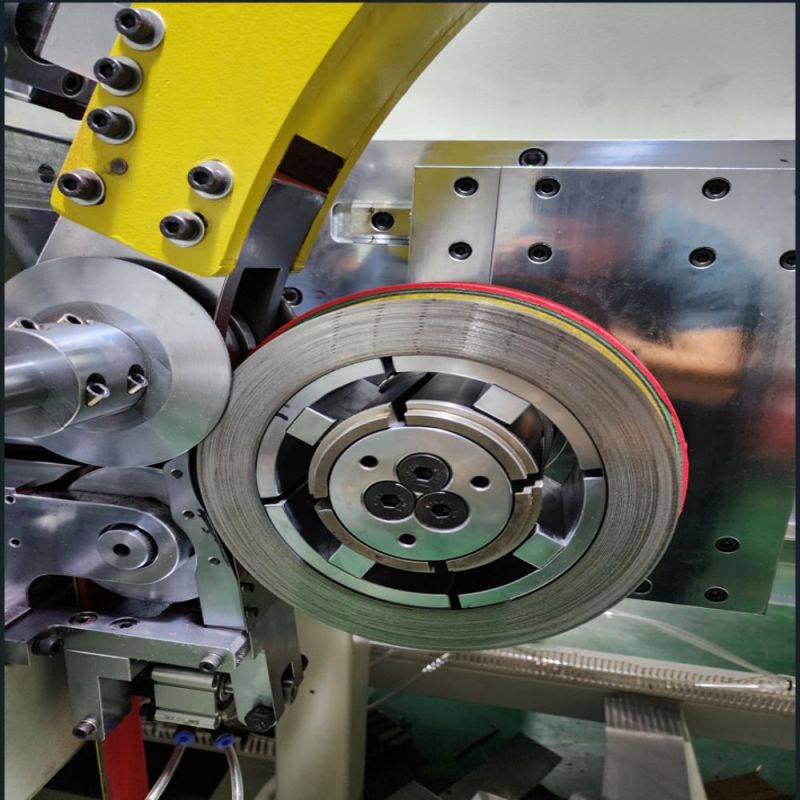

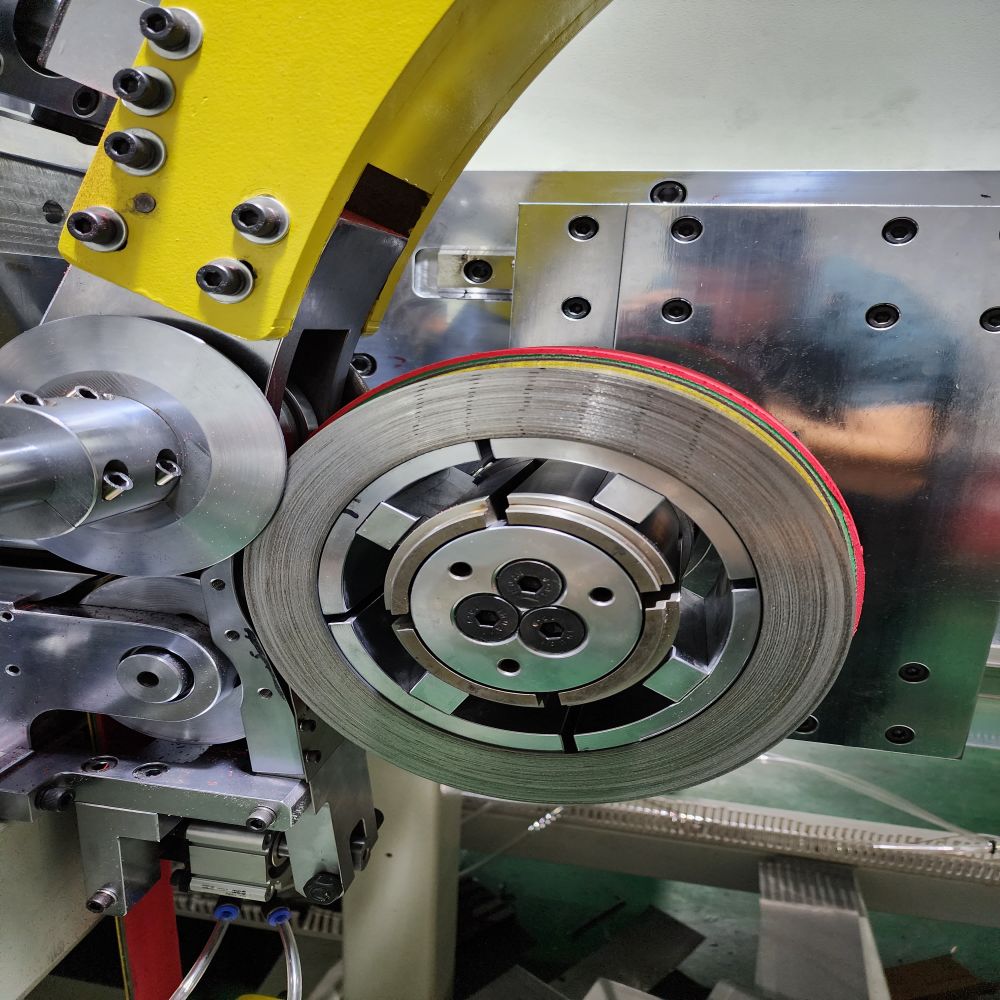

Adjustable vertical steps: The machine is capable of adjusting vertical steps from 2 to 15 to accommodate a variety of winding configurations. Each stage can accommodate 1 to 3 core sheets, providing great flexibility and adaptability for different winding needs.

Adjustable gas size and feed speed: Operators can easily adjust gas size and feed rate via the user-friendly HMI touch screen interface, ensuring precise control of the production process.

Advanced automatic winding technology: The adoption of automated packaging technology significantly reduces labor requirements and minimizes errors, thereby increasing overall productivity and product quality.

Enhanced durability: The machine is equipped with a tungsten steel cutting unit that ensures enhanced durability and service life even when operating under harsh conditions.

High quality components: The machine uses high-quality components, including Japanese SMC pneumatic components and European and Japanese electrical components. It uses German Siemens servo motors, imported servo reducers, linear guides, and bearings to ensure excellent performance and reliability.

With wound core toroidal winding machine s, you can achieve superior winding accuracy and efficiency. Its advanced functions, automated operation and versatile production capabilities make it an indispensable tool for wound core production in various industries.