01

Customized Gilled Transformer Radiator for Oil-immersed Power Transformer

Advantage

Efficient cooling: The transformer radiator is designed with a large surface area to effectively dissipate heat.

This ensures that the transformer remains within an optimal temperature range, preventing overheating and potential damage to the winding insulation. Enhanced Thermal Performance: The radiator core is composed of finned tubes to maximize heat transfer. These fins increase the surface area and provide a greater contact area with the cooling medium, thereby improving the overall thermal performance of the heat sink. Temperature Regulation: Transformer radiators utilize natural convection or forced air circulation to regulate temperature. Natural convection radiators benefit from the natural movement of air, while forced air cooling uses fans to enhance heat dissipation.

This flexibility allows cooling solutions to be tailored to specific operational requirements. Compact design: The transformer radiator is compact and lightweight, making it easy to install and maintain. Their space-saving design ensures that they can be placed in tight areas, thus optimizing the layout of the transformer installation.

Corrosion Resistant: The radiator is made of high-quality materials, such as aluminum or steel, which is corrosion-resistant. This resistance helps protect the heat sink from environmental factors such as moisture and chemicals, ensuring its longevity and reliability.

Feature

Material Selection: Transformer heat sinks are available in a variety of materials, including aluminum and steel. Aluminum radiators provide excellent thermal conductivity and are lightweight, while steel radiators provide robustness and durability in harsh operating environments.

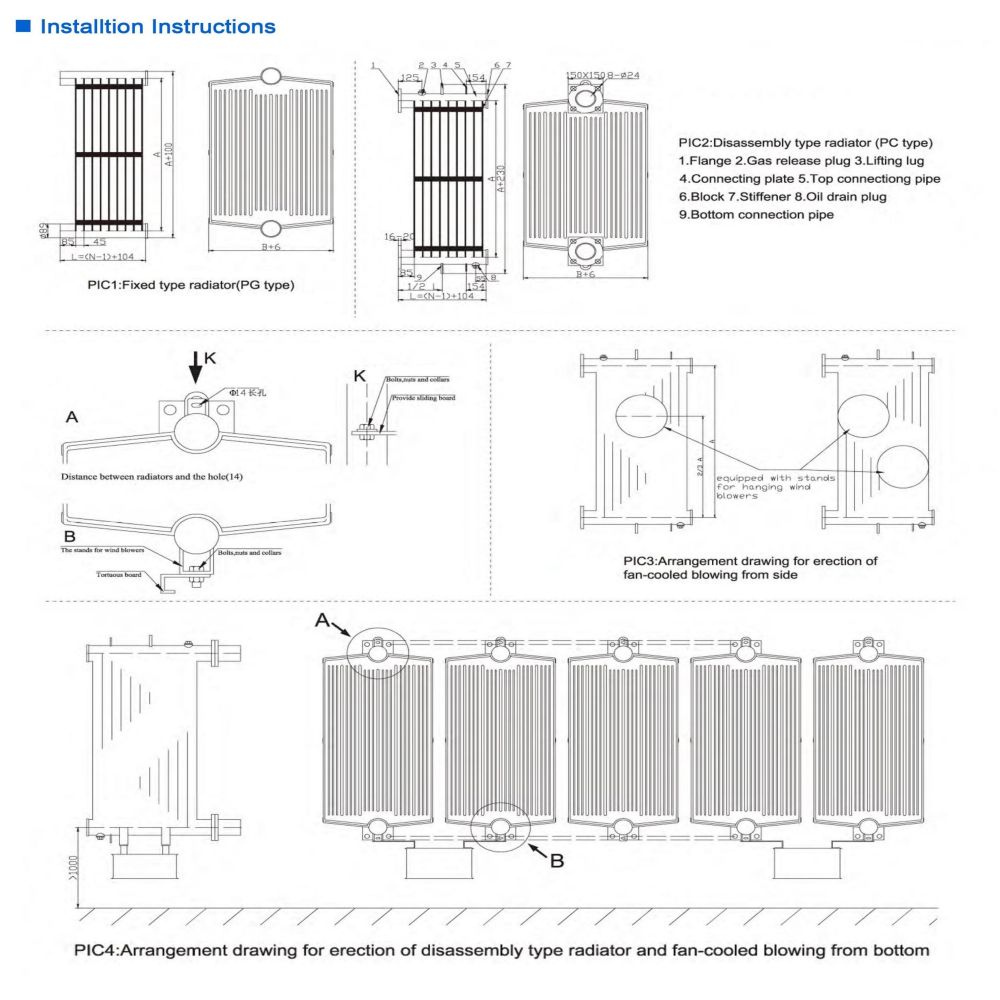

Configuration: Radiators are available in different configurations such as direct expansion or separate tank designs. The direct expansion design integrates the radiator into the transformer tank, while the split tank design allows independent installation of the radiator. These configurations provide the flexibility to match the heat sink solution to specific transformer requirements.

Accessories: Transformer radiators can be equipped with a range of accessories including butterfly valves, pressure relief devices, oil level indicators and drain valves. These accessories provide additional functionality and are easy to maintain.

Application

Transformer radiators are used in a wide variety of industries and applications, including: Power Distribution: Transformer radiators are an important part of the power distribution network, ensuring efficient operation of the transformer and preventing overheating. They are commonly used in substations and power generation facilities.

Industrial Transformers: Transformer radiators are widely used in industrial environments. Transformers play a vital role in voltage regulation and power transmission. Industries such as manufacturing, mining, oil and gas, etc. rely on transformer radiators to keep their electrical systems operating optimally.