01

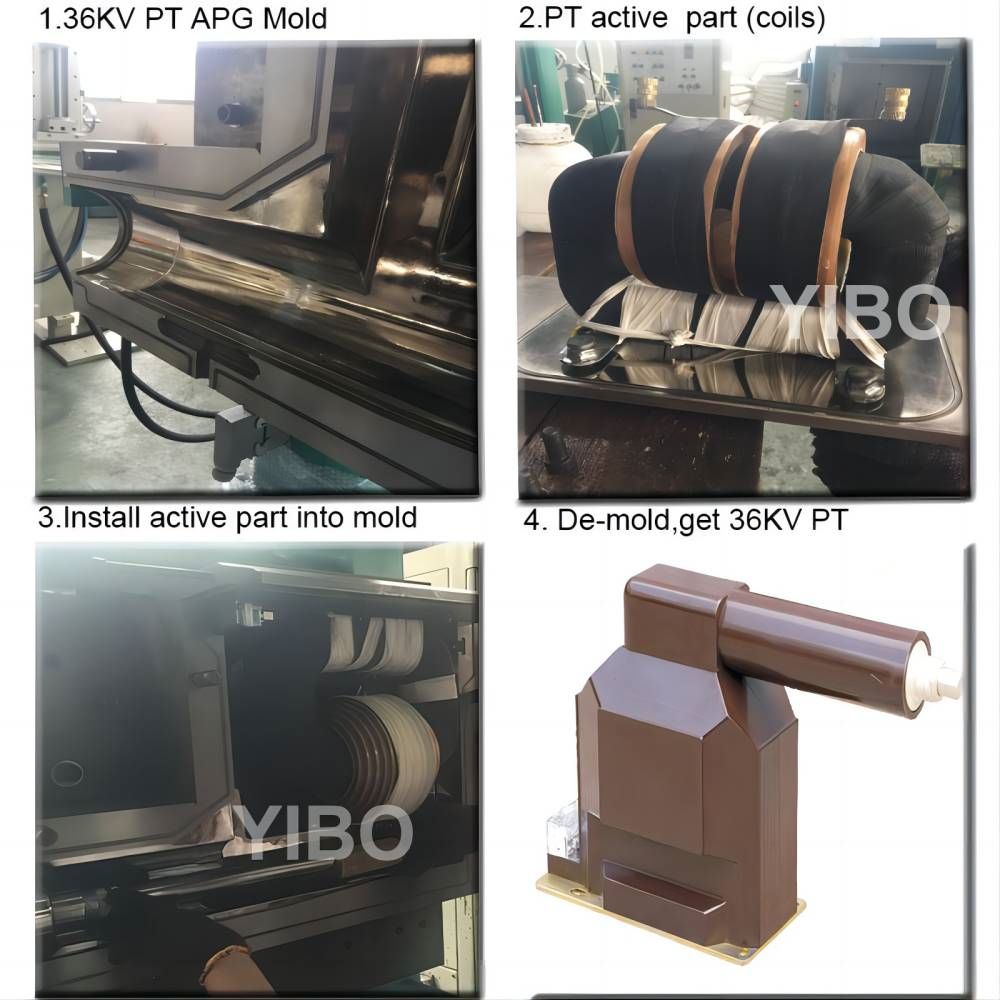

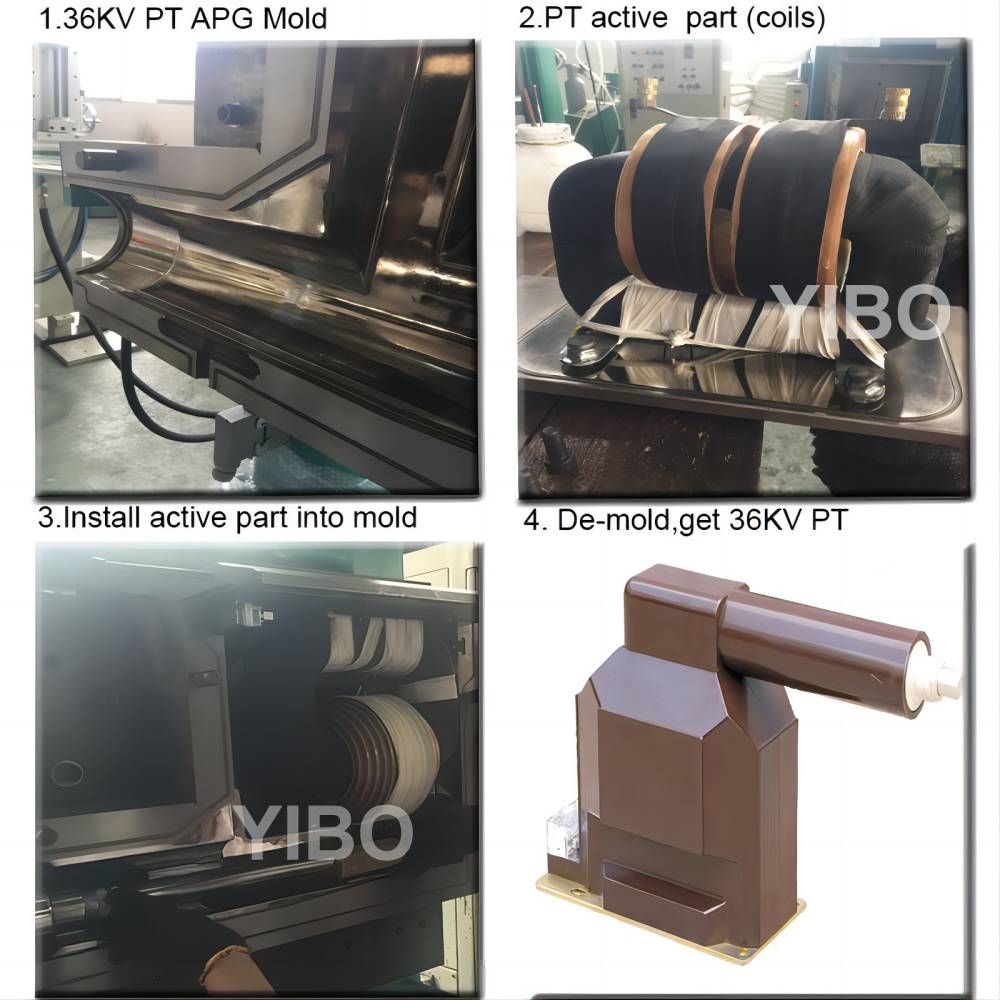

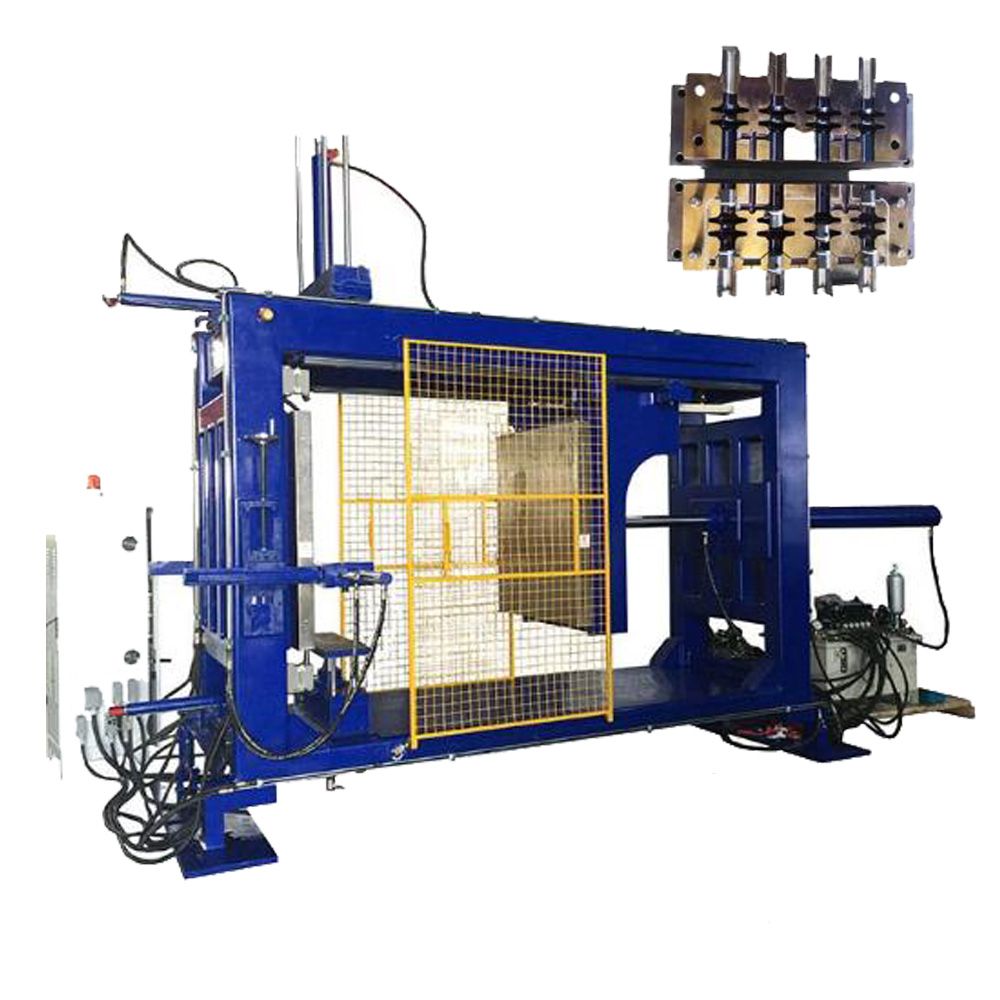

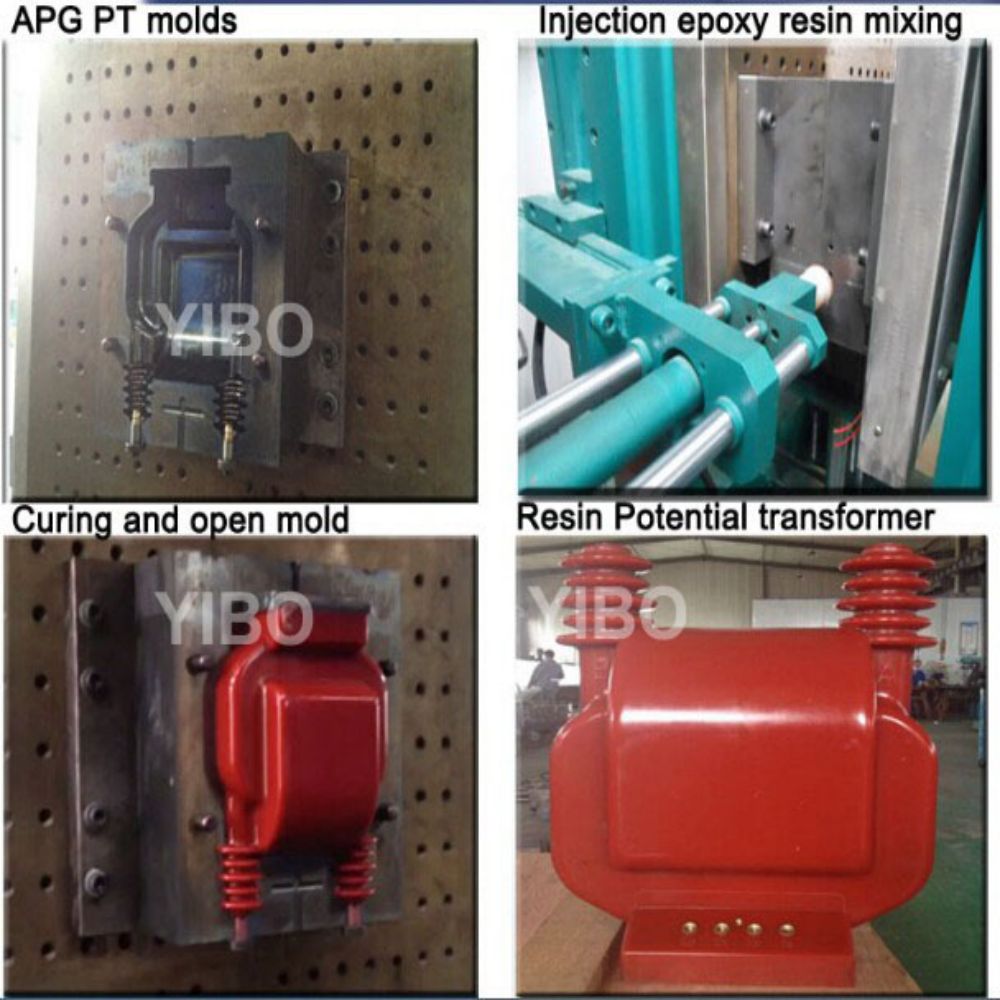

Cutting-edge APG pressure gel injection molding machine for the transformer industry

Applications

Voltage Transformer Manufacturing: Our APG pressure gel injection molding machines are ideal for producing voltage transformers used in power distribution networks, renewable energy systems and various industrial applications. It guarantees consistently high quality and reliable insulation for efficient power transmission.

Current Transformer Manufacturing: With advanced APG technology and precise injection capabilities, our machines are ideally suited to produce current transformers for power metering systems, power monitoring devices and electrical equipment. Ensure accurate current measurement and reliable performance.

Insulating component production: Our machines play a vital role in manufacturing transformer insulating components including bushings, insulators and encapsulated components. It ensures the production of strong, durable and high-performance insulation products required for reliable operation of transformers.

Product Advantages

APG technology output: Our machines adopt APG technology, which ensures the highest quality and precision of transformer insulation epoxy resin encapsulation. This advanced technology delivers superior electrical insulation properties and superior product performance.

Turnkey projects: We provide turnkey projects, providing customers with comprehensive solutions from equipment installation and commissioning to employee training. Our experienced team ensures smooth integration of our machines into your production line, saving you time and resources.

PLC fully automatic injection: The PLC fully automatic injection function ensures precise control of the entire injection molding process. This ensures consistent product quality, minimizes production errors, and increases manufacturing efficiency.

Leak-proof and Sturdy Frame: Our machines are built with a sturdy and leak-proof frame, ensuring reliable and accurate injection molding. This robust design prevents material leakage, ensuring the transformer components are of high quality and free of defects.

250KN clamping force: Our machine has a clamping force of 250KN, which provides a powerful and safe clamping mechanism. This ensures precise injection molding, resulting in high-quality, dimensionally stable products. Personalized customization: We understand the diverse needs of our customers. Our machines offer customization options, allowing you to customize the equipment to your exact requirements, ensuring optimal performance and maximum productivity. Features:Adopting advanced APG technology to achieve excellent insulation packaging Turnkey project for seamless equipment integration PLC fully automatic injection molding, precise control Leak-proof, sturdy frame ensures reliable molding250KN clamping force, precise injection Personalized customization, tailor-made solutions Invest in our APG pressure gel injection molding machines and experience the cutting-edge technology, efficient automation and superior quality they offer. Streamline your transformer manufacturing process and gain a competitive advantage in the industry.