01

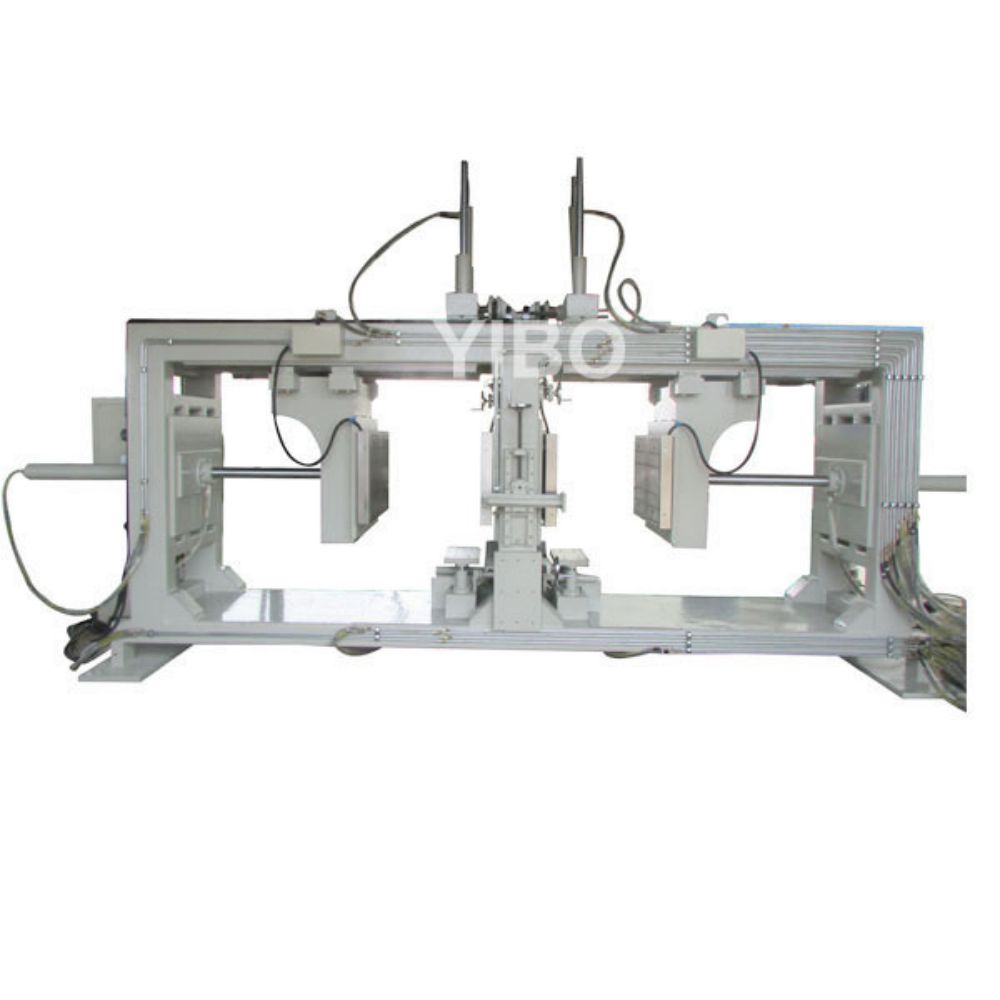

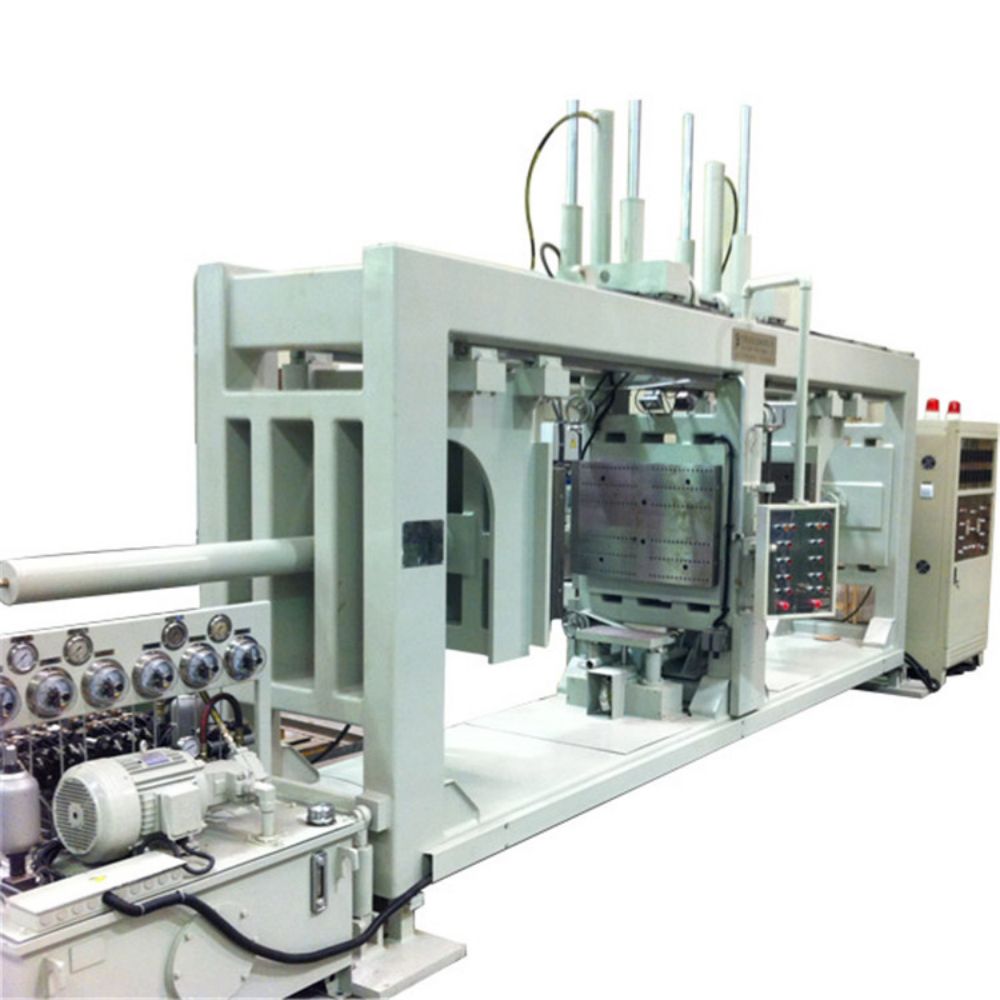

Double Station APG Clamping Machine

Machine frame part

Integral frame mechanism: annealing treatment after welding to eliminate internal stress

45 model linear guides, support and guide moving templates

Hanging moving plate

Main clamping pressure 200KN

Main closing cylinder: Piston diameter 125mm

The maximum distance between the two heating plates is 1750mm and the minimum distance is 200mm

Left and right horizontal clamping parameters

1.1 Station A,B horizontal formwork 900*600mm (Length×Width),

1. Maximum horizontal clamping force 250KN

1.3 The minimum closing distance is 240mm and the maximum opening distance is 1600mm

1.4 The movable template can carry the mold with a maximum weight of 5 tons

1.5 Closing movement speed is the fastest 3.2m/min and the slowest 1.8m/min

1.6 Heating power is 48KW 380V

1.7 Heating maximum temperature 300℃

Left and right core-pulling parameters

2.1 Top core-pulling template 640×240mmx40mm (Length×Width)

2.2 Maximum stroke 760mm

2.3 Maximum clamping force 7 tons

2.4 The fastest moving speed of closing is 3.2m/min

2.5 The moving template can carry the mold with a maximum weight of 1 ton

2.6 The reserved heating power for the mold is 4KW 220V

2.7 Heating the maximum temperature of 250℃ to pull the core

~ upper core-pulling moving plate; z

Upper core cylinder: stroke 800MM, piston diameter 80MM, stroke 400MM;

2.1 Top core-pulling template 650×260mmx45mm (Length×Width)

2.2 Maximum stroke 900mm

2.3 The maximum clamping force is 10 tons

2.4 The fastest moving speed of closing is 3.2m/min

2.5 Moving templates can carry molds with a maximum weight of 4 tons

2.6 The reserved heating power for the mold is 6KW 220V

~ Lower core cylinder: stroke 800MM, no digging pit, piston diameter 80MM, stroke

400MM;

~ The distance between the core drawing plate and the center of the equipment is: minimum 270MM, maximum 1020MM;

~ Translation cylinder: stroke 550MM;

~ Guide sleeve and guide post: 2 sets, diameter 50MM;

~ A core pulling plate 550*240MM, used to install the core pulling device under the mold;

~1 set of lower core-pulling cylinder and shifting cylinder and guide rail protection device to avoid rubber material damage to related moving parts

Pieces;

~ Related accessories: electrical socket, oil pipe, etc.

Up and down core pulling

~ lower core pulling moving plate;

Lower core-pulling cylinder: stroke 800MM, excavation pit, piston diameter 70MM, (stroke 400MM; Don't dig a hole)

~ The distance between the core pulling board and the center of the device is 270MM (minimum) and 1020MM (maximum).

~ up and down core pulling translation: stroke 500MM; (electric, screw lock)

Guide sleeve and guide post: 2 sets, diameter 65MM;

~ a 550*240MM core pulling plate, used to install the core pulling device under the mold;

1 set of lower core-pulling cylinder and oil moving cylinder and guide rail protection device to avoid the damage of relevant moving parts by glue;

~ Related accessories: electrical socket, tubing, etc.

PLC+ touch screen control

The operation interface is simple and clear, and the quotation operation can be displayed.

~ Device function, operation mode: manual, automatic, single step operation.

Operation rights: The writing and calling of the product process program requires a password to log in, to prevent the program from being modified and called at will or leaked.

~ Adopt segmented speed: the closing speed is controlled in stages to ensure production efficiency and protect the mold at the same time (divided into fast and slow speed and adjustable, automatic speed change when approaching the mold). Die pressure monitoring pressure relief: can automatically monitor the real-time pressure of the hydraulic cylinder, when the pressure exceeds the set value, automatic pressure relief.