01

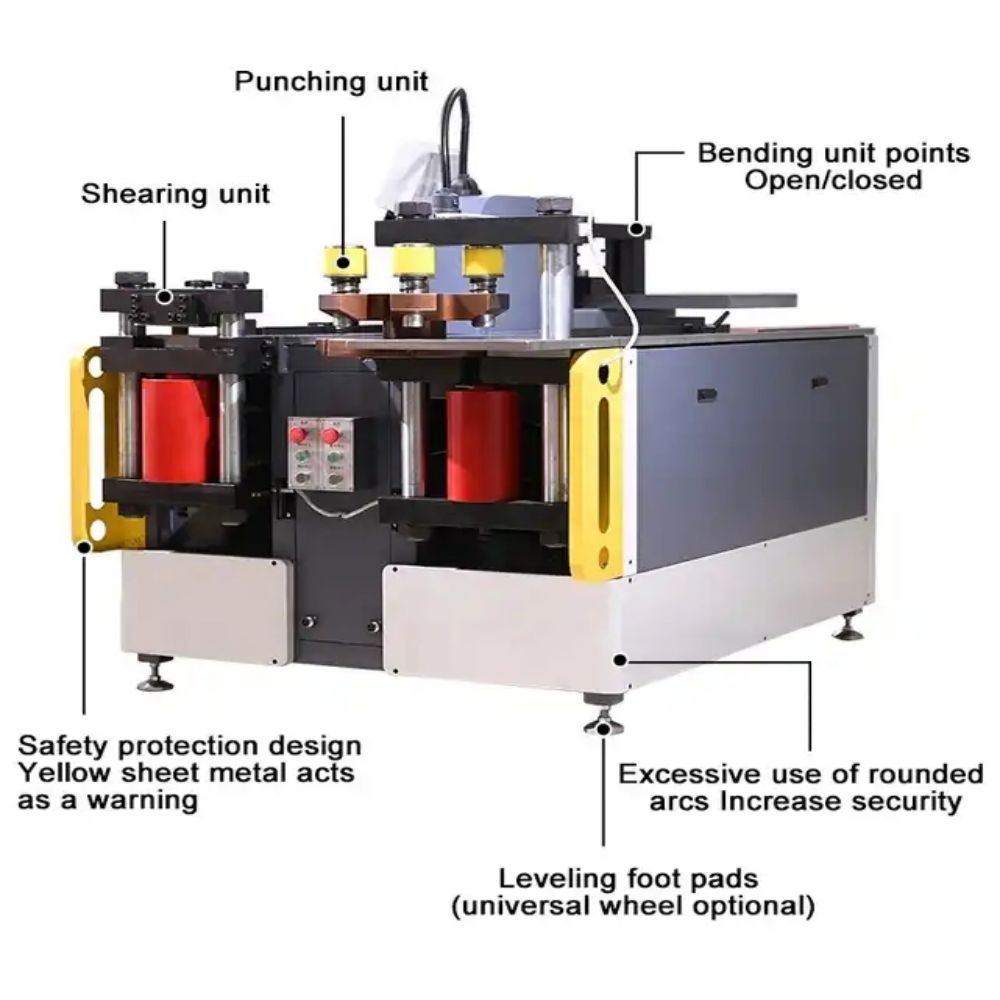

CNC busbar processing machine

▶Versatile processingcapabilities: The machine is equipped with three stations – punching, shearing and folding – enabling it to perform a range of processing tasks, including punching, shearing and bending of busbars.

Just change the mold to handle various workpiece requirements such as round holes, oblong holes, square holes, flat bends, vertical bends, embossing, flattening, twisting, crimping terminals, etc. This versatility eliminates the need for multiple machines, saving time and resources.

▶Improve workefficiency:CNC busbar processing machines rely on advanced CNC methods to significantly improve work efficiency. Automation of processes such as punching, shearing and bending eliminates manual labor and reduces the time and effort required for these tasks. As a result, productivity increases and higher output can be achieved in less time.

▶Improve ease of use:The machine is designed keeping user convenience in mind. Its intuitive interface allows operators to enter key parameters such as row thickness and bend angle into the system. The system then automatically calculates the connotation quantity and generates bending processing data. The operating display is a 5.7-inch color touch screen, making it easy to navigate and modify data as needed.

This user-friendly design simplifies the entire busbar machining workflow.

▶Accuracy and repeatability: The bending unit of the CNC busbar processing machine adopts horizontal processing method to ensure superior structural strength.

This design enhances the uniformity of flat bending and embossing, thereby improving accuracy and repeatability, especially during mass production.

The machine's grating ruler accurately controls the stroke to achieve precise and consistent bending, further improving product quality.

▶Customization and adaptability: The machine offers a wide range of customization options to meet different processing requirements.

Operators can easily supplement field data into the system at any time, allowing for real-time adjustments and parameter compensation.

Additionally, if non-standard artifacts are used, the system allows the user to set data according to the specific requirements of these artifacts. This flexibility ensures that CNC busbar processing machines can adapt to diverse customer needs.

▶Comprehensive control: In addition to the bending unit, the machine can also control punching and shearing units. Operators have complete control over the entire processing workflow, increasing operational efficiency and versatility. This comprehensive control enables users to achieve precise, accurate results with every operation.

▶Longevity andDurability:CNC busbar processing machines are built to last. Its structural strength and design help extend its service life and minimize maintenance and replacement costs.

With proper care and regular maintenance, the machine is guaranteed to have a long service life,