01

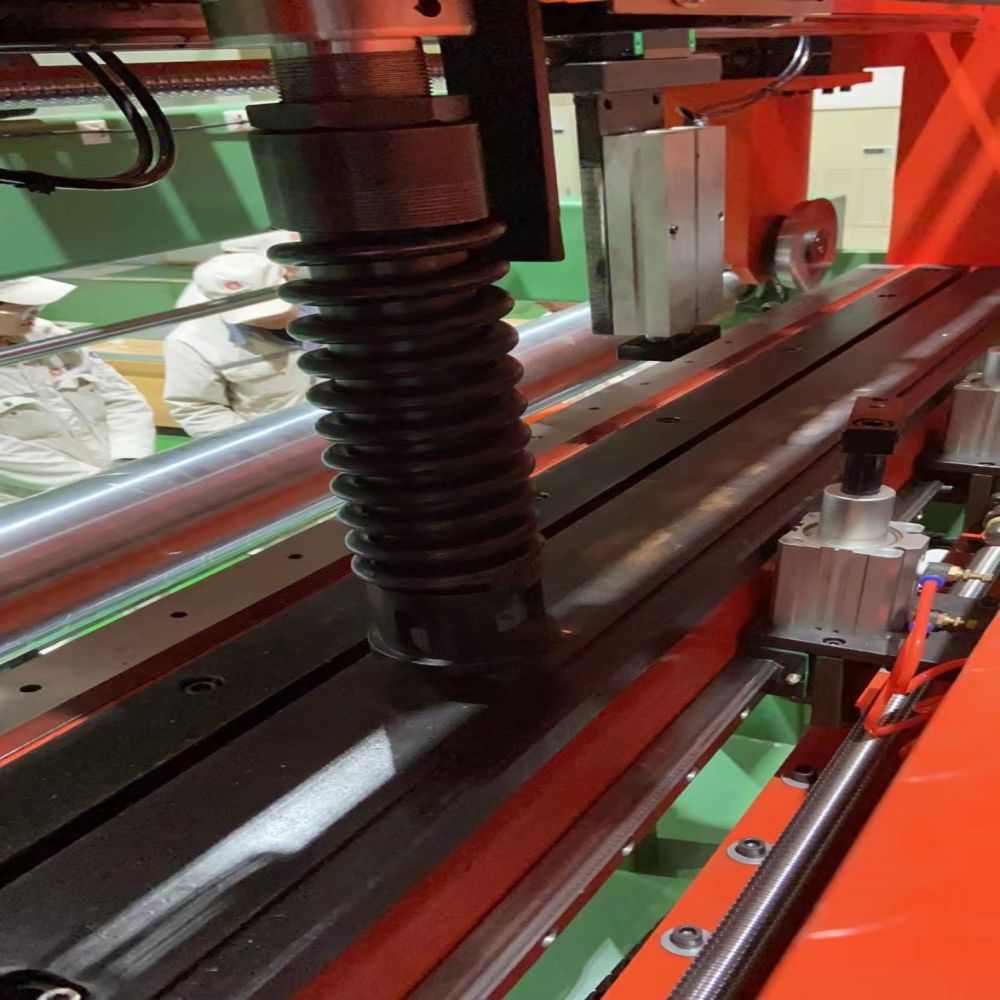

Cutting-edge cold welding foil winding machine for the transformer industry

Our cold welding foil winding machines are the ideal solution for transformer core manufacturing. It ensures safe and strong joints, enabling efficient power transmission in applications such as power distribution, renewable energy systems and industrial machinery.

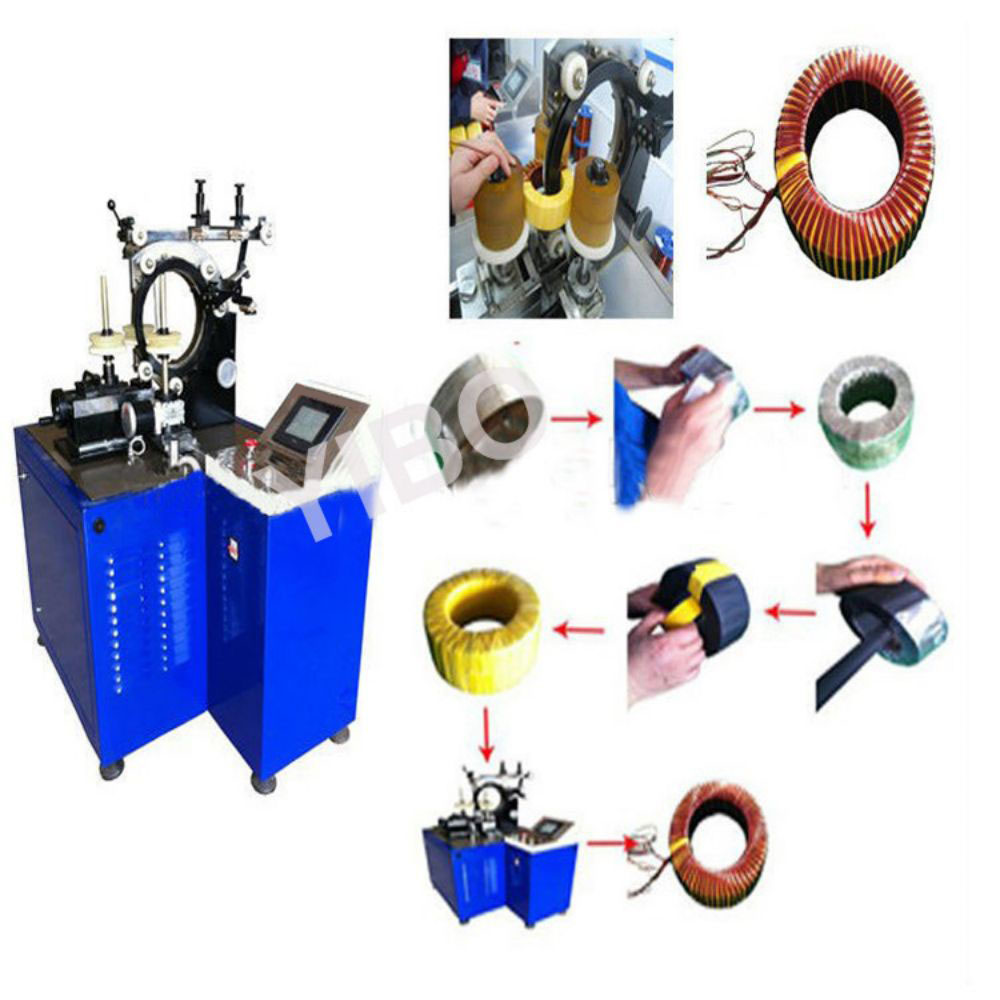

Transformer Coil Winding

Our machines are designed for versatility and can accommodate a wide range of transformers of different sizes and specifications. Its precise winding capabilities make it indispensable in industries such as telecommunications, automotive electronics, aerospace and medical devices.

Product advantages

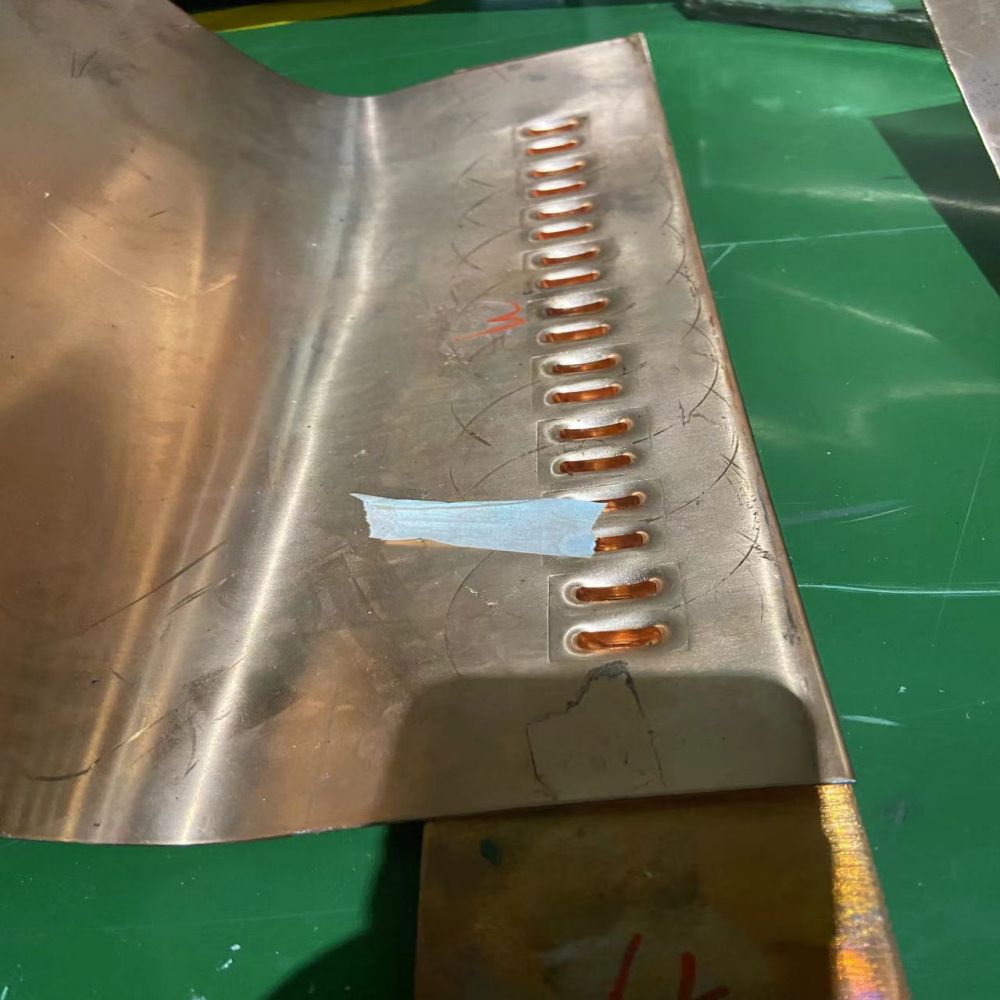

Cold Welding Expertise: Revolutionize your manufacturing process with our machines’ cutting-edge cold welding technology. By eliminating the need for heat-based methods, our machines ensure seamless and strong joints, resulting in a stronger transformer core. Wide Winding Range: Our machines are available in wide winding range from 600mm to 1600mm, providing the flexibility to handle various transformer sizes and requirements. This versatility improves manufacturing efficiency and meets diverse customer needs.

Servo Tension Control: Experience precise tension control throughout the entire winding process with our Servo Tension Control feature. This ensures uniform and consistent winding quality, minimizing material damage and improving the overall performance of the transformer.

Strong welding strength: The strong welding strength of our machines ensures a reliable and safe connection between foil layers. This is essential for efficient power transmission and ensuring optimal operation of the transformer.

High Precision and PLC Programming Control: Our machines offer high precision and flexibility through advanced PLC programming control. Users can easily program and adjust winding parameters such as speed, turns, pitch and tension, ensuring precise coil winding and minimizing waste.

Advanced Automation Increases Efficiency: With advanced automation features, our machines streamline the production process. It includes automatic foil feeding, cutting and gluing, reducing manual labor and production time. This advanced automation increases productivity, cost-effectiveness and reduces lead times. Extended service life and durability: Our machines are built with high-quality components and materials to ensure a long service life and excellent performance. It reduces maintenance requirements and downtime, thereby increasing operational efficiency.

Features

Advanced cold welding technology ensures strong joints wide winding range, 600mm to 1600mmServo tension control, precise winding Strong welding strength ensures reliable connection

High precision and PLC programming control for flexibility

Advanced automation features increase efficiency

Extended service life and durability for long-term use our cold welding foil winding machines are the ultimate solution for transformer manufacturers with their cutting-edge technology, wide winding range, precise tension control, strong welding strength, high precision, advanced automation and longer service life. Increase your production capabilities by investing in this state-of-the-art machine.