01

High vacuum pressure impregnation equipment for efficient material saturation

Our high vacuum pressure impregnation equipment provides efficient and precise impregnation of graphite using a variety of fluids, including pitch. The process enhances the material's properties, allowing it to operate seamlessly in applications such as electrodes, seals and lubricated components.

Cast Impregnation

With our equipment, cast products are effectively impregnated with epoxy resin, ensuring complete saturation of gaps. This increases mechanical strength, reduces porosity and increases resistance to environmental factors, resulting in high-quality castings.

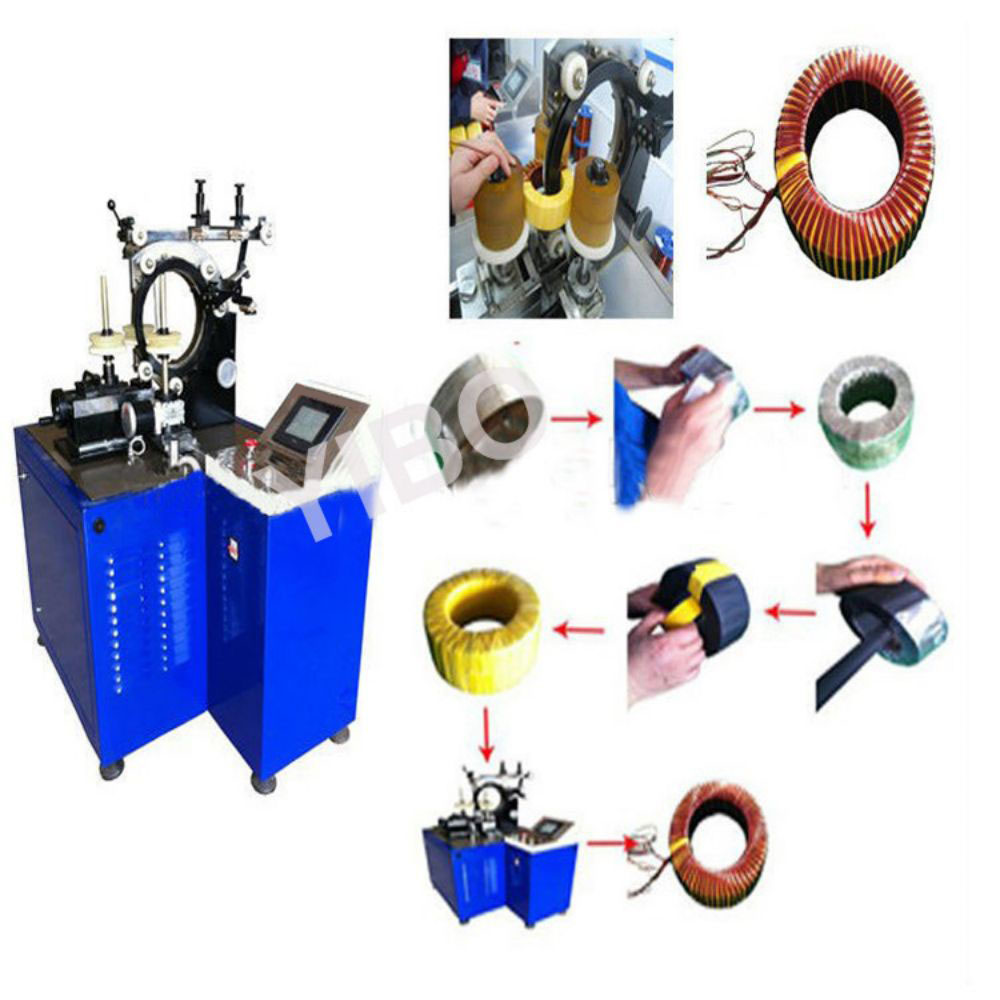

Electrical coil and component insulation: Our equipment is designed for the insulating treatment of electrical coils and components.

By impregnating the gap with an insulating varnish, components gain higher dielectric strength, improved thermal conductivity and greater resistance to electrical breakdown, ensuring reliable performance.

Custom Applications

Our high vacuum pressure impregnation equipment can be customized to meet the unique requirements of various industries. From individual process parameters to customized chamber dimensions, we provide solutions for specific needs, ensuring optimal performance and productivity.

Product advantages

Our equipment provides high vacuum during the impregnation process, effectively removing air and moisture from the product. This allows the impregnating fluid to better penetrate into the gaps, thereby increasing material saturation and enhancing product performance.

Stable quality

Our equipment is backed by an experienced team of engineers with more than 20 years of expertise, ensuring stable and consistent impregnation quality. Every aspect from design to manufacturing is carefully executed to guarantee reliable and high-quality results for our customers.

PLC fully automatic control

Our equipment adopts PLC fully automatic control, which can achieve precise and accurate impregnation control. This eliminates human error, ensures consistency in the impregnation process, and reduces the risk of product defects, resulting in increased efficiency and cost savings.

Personalization

We understand that every customer has unique needs. Our equipment offers personalized customization options to meet individual needs.

From adjustable process parameters to flexible chamber designs, we provide customized solutions to meet specific application needs.

Features:Vacuum pressure impregnation enables efficient and thorough saturation

Experienced engineers provide stable and consistent quality assurance

PLC fully automated control, accurate and error-free operation

Personalized customization options for optimal performance and productivity Invest in our high vacuum pressure impregnation equipment and improve the impregnation process in your industry.

Benefit from our high vacuum technology, consistent quality assurance, experienced engineers, fully automated PLC control and personalized customization options to achieve superior material saturation and enhance your product performance.