01

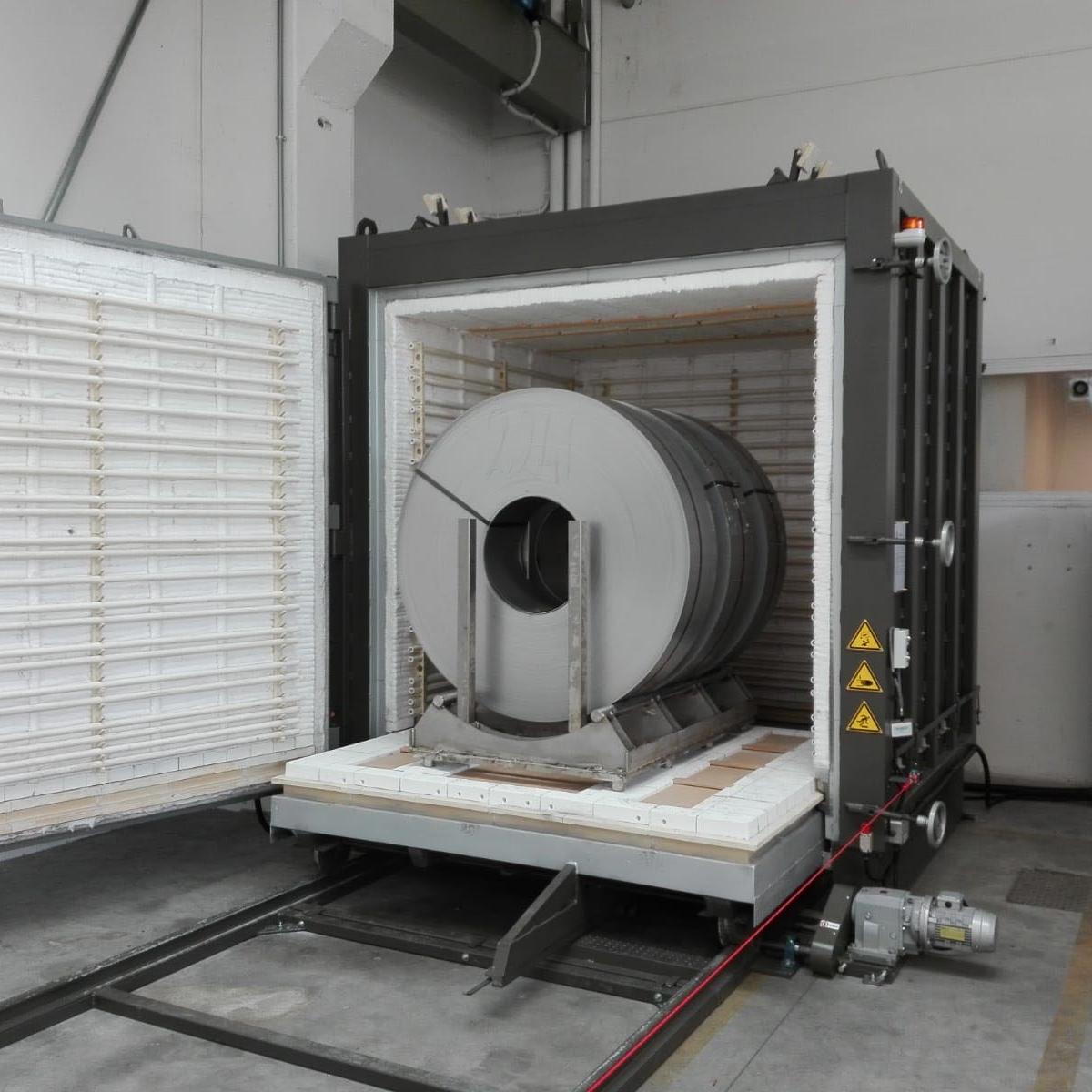

Vacuum Annealing Furnace

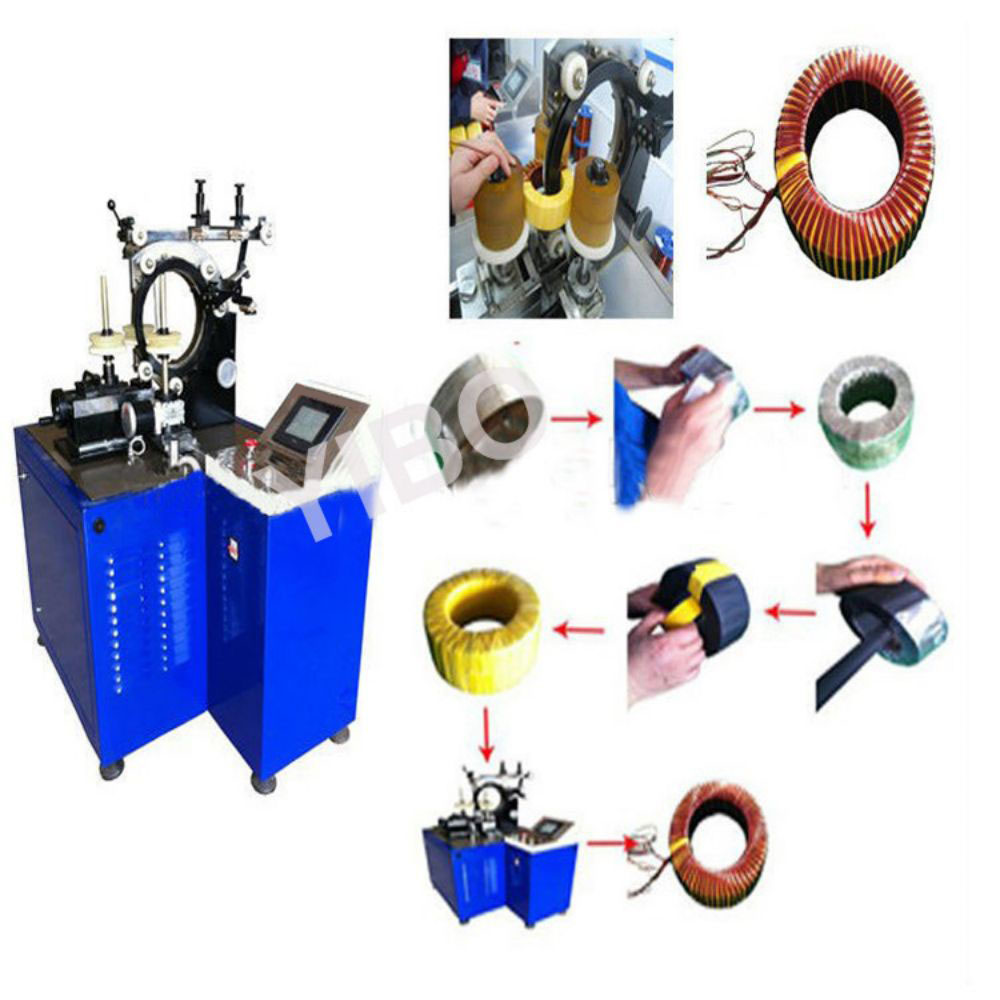

1.Just change the mold to handle various workpiece requirements such as round holes, oblong holes, square holes, flat bends, vertical bends, embossing, flattening, twisting, crimping terminals, etc. This versatility eliminates the need for multiple machines, saving time and resources.

2.This helps maintain the material's required chemical composition and mechanical properties, ensuring consistent transformer quality and reliability. In addition, the vacuum annealing process enables precise temperature control and uniform heating.

3.This allows the silicon steel sheet to be heated to the optimal annealing temperature and held at that temperature for the required time, thereby improving grain size and magnetic permeability. In addition, there is no air and moisture in the vacuum environment, which minimizes the risk of oxidation and contamination on the surface of the silicon steel sheet. This ensures a high-quality annealing process and reduces the need for additional cleaning or surface preparation steps after annealing.

4.In summary, the vacuum annealing furnace has significant advantages in the annealing process of transformer silicon steel sheets, including improved cleanliness, enhanced magnetic properties, controlled atmosphere, precise temperature control and reduced surface oxidation. These advantages contribute to the production of high quality and high performance transformers.

5.The vacuum environment provided by the annealing furnace eliminates oxygen and water, preventing oxidation and moisture on the material surface.

6.This ensures material purity, improves product quality, and reduces the need for subsequent cleaning and handling.

7.Precise temperature control and heating rate adjustment in the vacuum annealing furnace ensure uniform heating and cooling of the material. This is critical because proper annealing processes can improve the material’s grain structure and mechanical properties, thereby increasing product life and performance. In addition, the adjustable atmosphere function of the vacuum annealing furnace can meet the specific annealing requirements of different materials.

8.By changing the composition and pressure of the furnace atmosphere, it is possible to control the surface chemical reactions and thereby optimize the annealing results. In addition, vacuum annealing furnaces facilitate rapid heating and cooling, thereby improving production efficiency. In addition, the annealing process in a vacuum environment can reduce energy consumption and environmental pollution, which is in line with sustainable development goals. In summary, the vacuum annealing furnace process offers many advantages, including elimination of oxygen and moisture, precise temperature control, adjustable atmosphere, and rapid heating and cooling capabilities.

9.These advantages make vacuum annealing furnaces a valuable asset in various industries, improving product quality, increasing efficiency and gaining competitive advantage.