01

Vacuum Drying Equipment

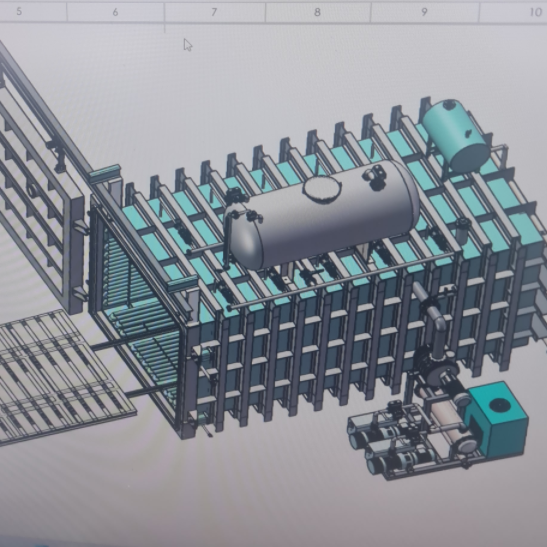

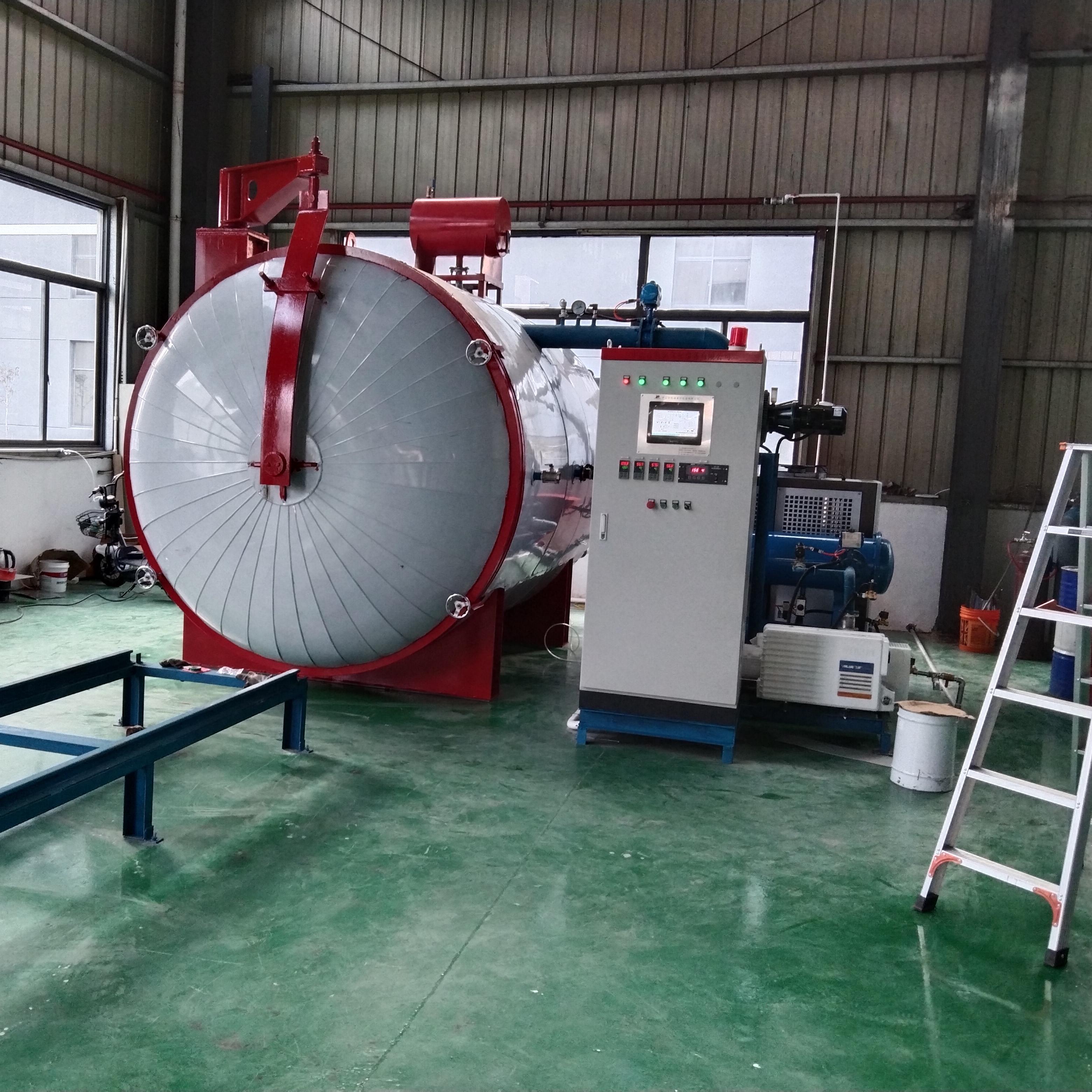

This equipment continuously changes the pressure in the drying tank to achieve uniform heating and temperature rise of the product during the drying process.

It can also promptly remove the evaporated moisture in the tank to prevent the iron core from rusting. The progressive drying method minimizes product deformation and ensures thorough drying. The equipment has a reasonable structure and process design.

Compared with traditional vacuum drying methods, the drying time is reduced by about 40%. It is a reliable, efficient and energy-saving processing equipment.

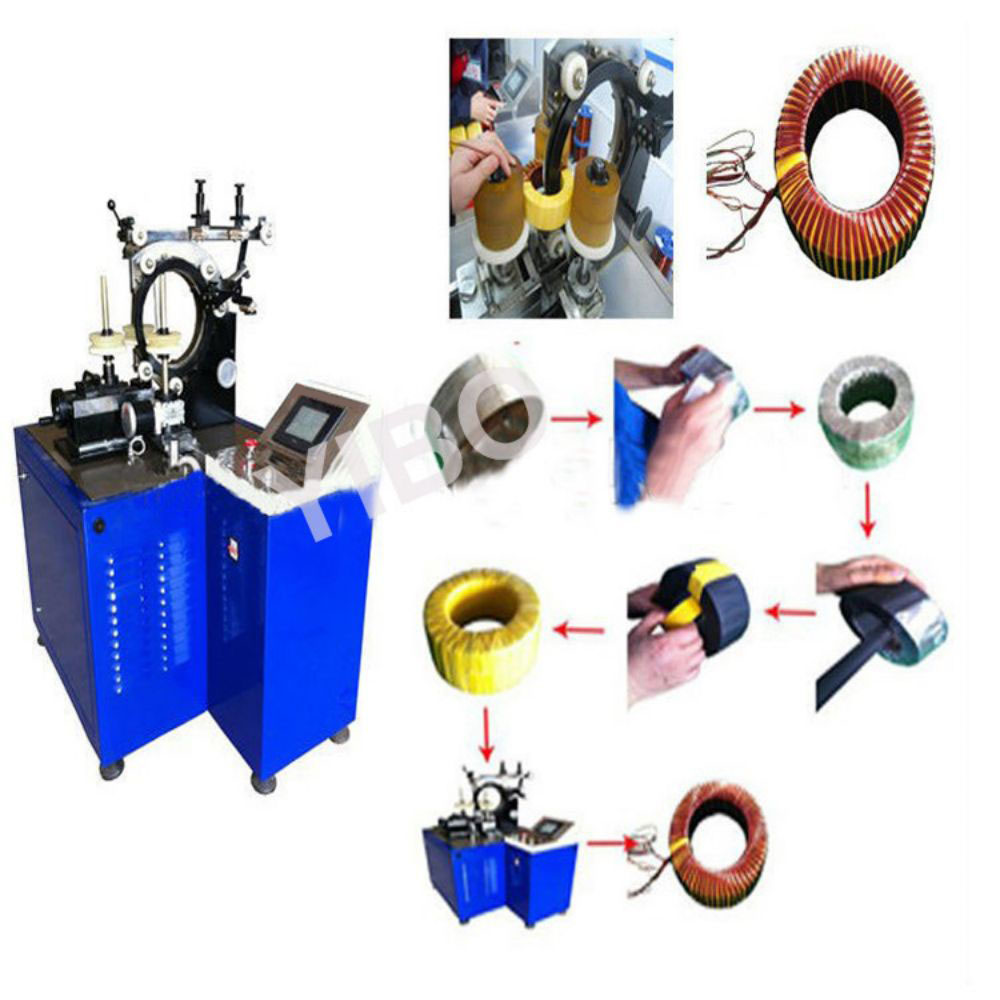

Used for drying and handling electrical products, including transformers below 35KV.

The device has the following technical features: The vacuum system is designed with a new condenser, which can cool down most of the moisture in the product and condense it into water for discharge, effectively preventing water contamination of the vacuum pump during the drying process.

A high-temperature magnetic pump is used to transport thermal oil to ensure a more stable heating system and prevent oil leakage.

During the heating process, pressure exchange technology is used multiple times according to the temperature of the equipment to regularly reduce the pressure in the vacuum tank to a certain value.

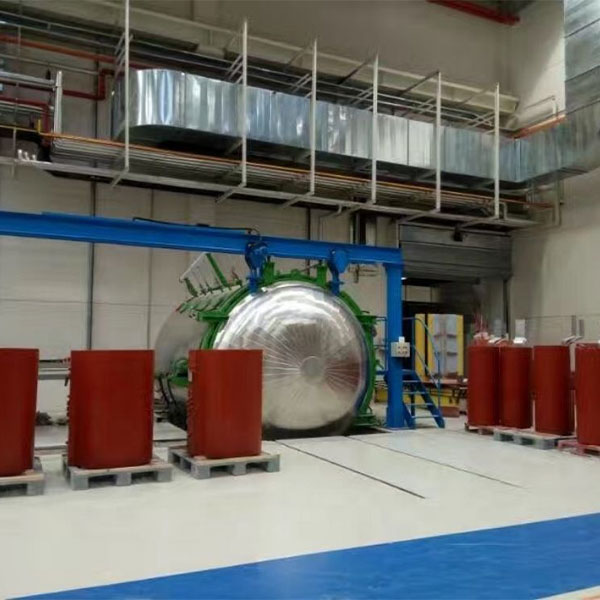

This creates the most suitable conditions for the evaporation of moisture inside the insulating components, ensuring that the evaporation process is at its best during drying. This equipment scientifically controls the drying process through the voltage transformation method and combines domestic and foreign technologies to effectively solve the problem of rust during the drying process of the iron core.

The automation level and processing technology adopted by the equipment have reached domestic advanced standards.

The quality of the processed products can reach the level of high-end products in the industry. The equipment electrical control system and various components are stable and reliable, ensuring continuous performance in production and use.